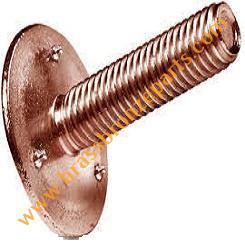

Bronze Foundation Bolts

Product Details:

- Head Type Hooked, L-Type or J-Type head options

- Thread Type Metric and UNC threaded options available

- Heat Treatment Not usually required; supplied in annealed condition

- Thickness Customizable, typically ranging from 10 mm to 50 mm depending on application

- Diameter Available from 12 mm up to 50 mm

- Dimension (L*W*H) Dimensions can be tailored; sample size 250 mm (length) x 25 mm (width) x 25 mm (height)

- Length Ranges from 150 mm to 1000 mm or as required

- Click to View more

Bronze Foundation Bolts Product Specifications

- Available from 12 mm up to 50 mm

- Designed for securing heavy structures and machinery to concrete foundations

- Conforms to IS, ASTM, and DIN standards

- Customizable, typically ranging from 10 mm to 50 mm depending on application

- Dimensions can be tailored; sample size 250 mm (length) x 25 mm (width) x 25 mm (height)

- Ranges from 150 mm to 1000 mm or as required

- Polished, anti-corrosive coating

- Hooked, L-Type or J-Type head options

- CuZn39Pb3 (Bronze) as standard grade

- Metric and UNC threaded options available

- Not usually required; supplied in annealed condition

Product Description

With the aid of our sound distribution channel, we are capable to deliver these Bronze Metric Bolts across the globe on time. The provided bolts are widely used for fastening various automotive, marine and other industrial equipment in a secure manner. These bolts are manufactured by our skilled professionals using supreme quality bronze. Besides, the offered Bronze Metric Bolts can be purchased from us in numerous dimensions in bulk.

Features:

- Easy to tighten

- Sturdy design

- Excellent threading

- Accurate dimension

Materials and Standards

| Tin Bronze | ASTM B30 C92600, C92600, PB102, BS1400(Pb1),BS 1400 GI |

| Aluminum Bronze | ASTM B 111 C60800/ASME SB 111 C 60800 /EN 12451 CuAL5AS / CW200 / C61400 / C95400 / C61800 / C62300 / C62400 / C62500 / C95200 / C95900 / CuAL11Ni5Fe5, BS1400-AB1 & AB2, BS2874 CA104 & Ca103 / CW300G/ CW303G |

| Aluminum Silicon Bronze | ASTM B 150 C 64200 / SAE J 463 C 64200 / C63600 / C65620/ C65100 / C65300 / C65500/ C65610 / CW301G/ CW115C / CW116C |

| Leaded Commercial Bronze | ASTM B 140 C31400 |

| Phosphorous Bronze | ASTM B103 C 51000/ SAE J 463 C51000/ BS2874 PB 102 |

| Manganese Bronze | C67300/ C67500/ C66800/ C67400/ C67600/ C86200/ C67000/ CW704R |

| Nickel Aluminum Bronze | C63000/ C63020/ C63200/ C95510/ C95500/ C95520/ CuAL10Ni5Fe4/ CW307G/ C95800/ C96900 IS 10569: 1983 Grade 1,2&3 / CW308G |

| Silicon Bronze | C65500 ASTM B96/ ASTM B98/ ASME SB96/ ASME SB98 |

Feature:

- Resistant to corrosion (Also resists salt water corrosion), Thus highly used in Coastal (Marine) applications.

- Good to use in heavy load & High pressure application.

- Melting point of bronze is higher in comparison to other metals.

- Hardness & Strength is a quality of bronze alloys.

- Bronze is Non-Sparking (Spark Free) material.

Size:

| Bolts | Metric | M2, M3, M4, M5, M6, M7, M8, M9, M10, M11, M12, M13, M14, M15, M16, M17, M18, M19, M20, M21, M22, M23, M24, M25, M26, M27, M28, M29, M30, M31, M32, M33, M34, M35, M36, M37, M38, M39, M40, M41, M42, M43, M44, M45, M46, M47, M48 & As Per Customer Specification | Length As Per Customer Requirement |

| Inch | 1/4" to 2" & As Per Customer Specification | Length As Per Customer Requirement |

Packing: High quality export standard packing provided in form of Wood case, Carton, Wooden Pallets and as per requirements of customer.

Delivery Time: In given time.

Exemplary Corrosion Resistance

Thanks to the high copper content and specialized alloy composition, these foundation bolts demonstrate superior resistance to corrosion. This attribute ensures dependable performance in marine, chemical, and harsh industrial conditions where standard fasteners would degrade quickly.

Versatile Installation Methods

Bronze Foundation Bolts are compatible with cast-in-place and post-installed techniques, offering flexibility for various concrete foundation needs. With metric and UNC threading alongside customizable dimensions, they adapt easily to numerous structural requirements.

FAQs of Bronze Foundation Bolts:

Q: How are Bronze Foundation Bolts typically installed in concrete structures?

A: Bronze Foundation Bolts are installed either by being cast-in-place during concrete pouring, or by post-installation into pre-drilled anchor holes. Both methods ensure a secure and reliable attachment for heavy structures and machinery.Q: What benefits does the bronze alloy provide over standard steel foundation bolts?

A: The high-grade bronze alloy, particularly CuZn39Pb3, significantly enhances corrosion resistance, especially in marine and chemically exposed environments. This extends the lifespan and reliability of the bolts in applications where steel fasteners might deteriorate quickly.Q: Where are these bronze bolts most commonly used?

A: They are predominantly used in marine, chemical, or industrial environments for securing heavy machines and structures to concrete bases. Their exceptional resistance to corrosion makes them ideal for such demanding conditions.Q: What customization options are available for these bolts?

A: Customizations include dimensions, thickness (from 10 mm to 50 mm), length (150 mm to 1000 mm), diameter (12 mm to 50 mm), thread type (metric or UNC), and head type (Hooked, L-Type, or J-Type), allowing adaptation to project-specific requirements.Q: What is the usual minimum order quantity for Bronze Foundation Bolts?

A: The typical minimum order quantity is 50 pieces. However, this may vary as per the manufacturers supply terms, especially for large-scale orders or special customizations.Q: What standards do Bronze Foundation Bolts adhere to?

A: These bolts conform to leading industry specifications including IS, ASTM, and DIN standards, ensuring high-quality manufacturing and performance consistency.Q: What is the operational temperature range and strength of these bolts?

A: Bronze Foundation Bolts operate effectively between -20C to +120C, with a tensile strength of 300-400 MPa and an approximate yield strength of 220 MPa, making them robust for demanding applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Bronze Bolts' category

we mainly deals in Countries like Middle east, Europe, North America, South America

|

SHREE EXTRUSION LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |